How Spring Anchors and Custom Springs Contribute to Modern Manufacturing

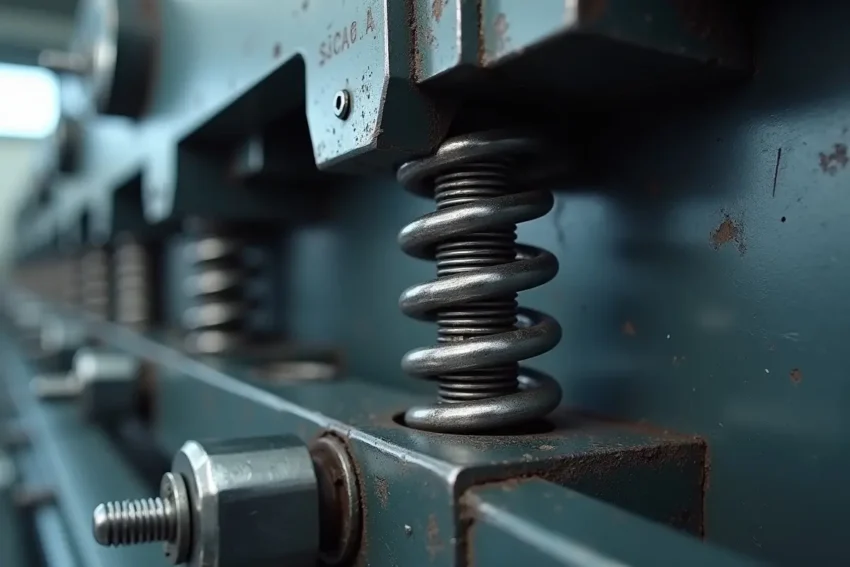

Modern manufacturing thrives on unmatched precision, operational efficiency, and unwavering reliability, all of which hinge on the seamless performance of seemingly small components, such as spring anchors and custom springs. Although they may be overlooked in the grand design of heavy machinery or intricate technology, these elements are fundamental to ensuring that manufacturing equipment performs consistently under demanding conditions. Their role stretches beyond simple mechanics; these parts are at the heart of preventing production bottlenecks, machine failure, and costly downtime.

For example, products such as the Heli-Tube® spiral cable wrap demonstrate how an innovative solution can manage complex cabling and provide effective tension management in automated settings. By mitigating wear and deploying tailored tension control, spring anchors and custom springs help companies uphold competitive quality standards in sectors ranging from large-scale automotive assembly lines to precision electronics manufacturing.

Though end users seldom notice their presence, spring anchors serve as the lifelines of assemblies where controlled tension and steadfast attachment are non-negotiable. Their function is critical: holding tension springs in place, absorbing shocks, and providing rapid tension adjustments to keep machines running at optimal performance levels.

In tandem, custom springs are developed for applications or machinery where standard springs would fail—these bespoke solutions are engineered down to the last millimeter to cope with targeted mechanical and environmental demands. Their precision not only boosts the overall efficiency of industrial setups but also significantly extends the lifespan of mission-critical equipment, safeguarding investments and sustaining innovation across diverse sectors.

Spring anchors and custom springs stand as proof of continuous advancements in materials science and state-of-the-art manufacturing techniques. Today’s components undergo meticulous design and rigorous testing, with engineers leveraging everything from high-performance alloys to advanced composites that offer increased durability, flexibility, and resistance to wear.

The evolution of these parts maintains momentum amid rapid technological change, whether the goal is withstanding the heat and vibrations of aerospace systems or enduring the repetitive stresses of industrial robotics. Their dependability underpins the smooth functioning of automated production lines, delicate surgical devices, and even the latest consumer electronics.

Manufacturers are pushing boundaries with ever more sophisticated equipment, digital tooling, and rigorous compliance standards to ensure that springs and anchors not only meet but often exceed industrial expectations. Routine and extreme operational conditions demand robust solutions, which is why spring components are designed to evolve alongside the machinery they support. By continuously refining these elements, manufacturers guarantee increased flexibility, reliability, and cost-effectiveness, empowering businesses to thrive in a fast-paced, quality-driven marketplace.

Contents

The Role of Spring Anchors in Manufacturing

Precision in Attachment and Tension Control

Spring anchors are indispensable points of support in the intricate machinery, playing a central role in managing the forces generated by tension springs. Beyond the basic function of attachment, these anchors enable fine-tuning of tension—an aspect paramount for applications that require consistent, repeatable force, such as assembly lines or automated handling systems.

In automotive suspension systems, for example, spring anchors secure and position extension springs that absorb road shocks and maintain chassis stability. This function goes far beyond passenger comfort; it profoundly influences the vehicle’s handling, safety profile, and ability to transport goods without damaging sensitive cargo. These anchors help balance dynamic forces, improve fatigue life, and enable the seamless operation of countless mechanical processes.

Supporting Automation and Advanced Manufacturing

The growth of smart factories and advanced robotics has driven demand for even more reliable and precisely machined spring anchors. They hold springs at set tensions within robotic grippers, actuators, and conveyor mechanisms, ensuring every move meets programmed parameters. Operations such as automated packaging, high-speed sorting, and assembly tasks would risk inaccuracies or failures without the steady force delivered by well-anchored springs.

By enabling rapid adjustments and robust securing of tension elements, spring anchors have enabled manufacturers to automate repetitive and complex processes with confidence. These improvements enhance productivity, facilitate innovation, and help manufacturers scale operations while safeguarding workers and optimizing energy consumption.

Custom Springs: Tailored Solutions for Specific Needs

Meeting Industry-Specific Demands

Custom springs address complicated challenges that off-the-shelf variants cannot solve. Industries like aerospace, with its unyielding requirements for reliability and weight reduction, depend on springs custom-designed for tightly controlled movements and manufactured from high-grade materials to resist thermal cycling, vibration, and corrosive atmospheres.

In the medical sector, customized springs enable the precise, repeatable motion of critical surgical tools, biopsy devices, and diagnostic assemblies, often in miniaturized form. Every custom spring represents a tailored response to specific application requirements, involving technical collaboration between engineers, end users, and metallurgists. Unique properties, such as non-magnetic alloys, biocompatibility, and ultra-high fatigue resistance, emerge through this process, elevating the utility and lifespan of the final product.

Endurance in Harsh Environments

Operating in extreme environments—such as those found in oil and gas fields, chemical plants, or deep-sea exploration—requires springs engineered to withstand high stresses, corrosive environments, and constant fluctuations in pressure and temperature. These springs are manufactured from robust alloys and corrosion-resistant coatings and are subjected to extensive fatigue and load testing.

The result: springs that maintain their properties and performance across a wide range of conditions, minimizing equipment downtime and reducing the need for frequent, expensive maintenance. This reliability translates to safer operations, greater productivity, and reduced total cost of ownership, all critical factors for high-stakes industries.

Advancements in Materials and Manufacturing Techniques

The past decade has been marked by exceptional progress in the development and application of novel materials for spring manufacturing. Stainless steel, which offers both strength and corrosion resistance, has become a staple, while nickel alloys and engineered composites are increasingly specified for their high performance in specialized applications. Beyond the materials themselves, manufacturing techniques have adopted cutting-edge technologies such as CNC coiling, laser-based measurement, and robotic quality inspection.

These improvements reduce manufacturing inconsistencies, support mass customization, and expedite time-to-market for new spring designs. Automated quality control—enabled by high-resolution imaging and machine learning—also ensures each produced spring and anchor meets stringent requirements. As outlined by Scientific American, the integration of digital manufacturing has been a catalyst for enhanced consistency and innovation in modern component production.

Applications Across Industries

Spring anchors and custom springs play critical roles in industries where precision, reliability, and strength are non-negotiable. The automotive industry relies on these components not just for suspension and shock absorption, but also in valve assemblies, clutches, and transmission systems. Aerospace applications span everything from actuating wing flaps to deploying landing gear systems.

Medical device manufacturers design tiny, highly specialized springs for use in everything from heart valves to precision laboratory equipment. The adaptability and scalability of these components allow for creative engineering solutions that comply with stringent regulatory frameworks while meeting operational and safety requirements.

In electronics, where both miniaturization and high performance are essential, springs and anchors are used in connectors, circuit board components, and complex switches for computers, telecommunications, and consumer electronics. Here, reliability over countless operational cycles and resistance to corrosion or electrical wear are crucial. These components might be micro-sized, but their failure could render entire assemblies inoperable, highlighting their critical importance even in the smallest of technological devices.

Ensuring Quality and Compliance

Maintaining consistently high quality is non-negotiable in spring and anchor manufacturing. Top-tier suppliers follow rigorous processes, including material traceability, batch testing, and computer-aided inspection, to ensure every component matches exacting tolerances.

Adherence to internationally recognized standards such as ISO 9001 and industry-specific benchmarks from organizations like the Aerospace Industries Association is standard for reputable manufacturers. Such standards require thorough documentation, detailed production protocols, and systematic endurance testing, all aimed at guaranteeing performance in critical applications.

This quality and compliance framework gives customers confidence that their parts will perform safely and reliably. The emphasis on standards is reinforced by groups such as the National Institute of Standards and Technology (NIST), which advocate rigorous process controls and the continual improvement of component engineering.

Future Trends and Innovations

The future of spring anchor and custom spring development is bright, as the sector embraces new digital and analytical technologies to drive improvements in product design, manufacturing, and lifecycle management. Artificial intelligence allows engineers to forecast spring performance, predict failure mechanisms, and optimize designs before prototypes are ever built.

Digital twin technology is already making waves—simulating how springs and anchors will behave under real-world stresses, this tool accelerates research, streamlines prototyping, and minimizes waste. Combined with sustainable practices, including the use of recycled metals and less energy-intensive manufacturing methods, these advances help the industry respond to rising environmental expectations without sacrificing product quality or performance.

As industries demand ever more reliable and sophisticated machinery, spring anchors and custom springs will remain at the cutting edge of manufacturing innovation, delivering both operational advantage and environmental responsibility.

Conclusion

Spring anchors and custom springs are fundamental to reliable, safe, and efficient machinery in the modern world. While their appearance may be humble, their performance shapes the quality and productivity of everything from daily transportation to life-saving medical procedures.

As technology evolves, with advancements in materials and intelligent design, these components will continue to support new breakthroughs in global manufacturing. They not only empower engineers to solve complex challenges today but also pave the way for tomorrow’s innovations—cementing their role as indispensable assets in maintaining operational excellence and driving industry progress.