What’s the Best Way to Set Up a Fire Fighting Pump for Home Use?

When preparing your property for fire emergencies, having the right tools in place is important. Choosing the right fire fighting pumps for home is necessary. Look for options created specifically for high-pressure output and compatibility with standard hoses, such as those found in some high-pressure models. Regular maintenance and testing of all equipment help guarantee that the setup works smoothly when it’s needed most.

It’s also smart to store hoses and fittings in an accessible, weather-protected area. Make sure everyone in your household knows how to operate the system in case of an emergency. A little preparation now can prevent major damage later.

Contents

Key Takeaways

- Choose a high-pressure, reliable pump and secure water source.

- Use quality hoses, fittings, and test the setup regularly.

- Proper placement and safety checks are essential for home fire protection.

Fundamentals of a Home Fire Fighting Pump Setup

A proper home fire fighting pump system depends on matching pump size and pressure to the available water source, ensuring all hoses and fittings are appropriate, and setting up the installation to maximize safety and performance. Attention to detail and the right equipment are essential to keep the system reliable in emergencies.

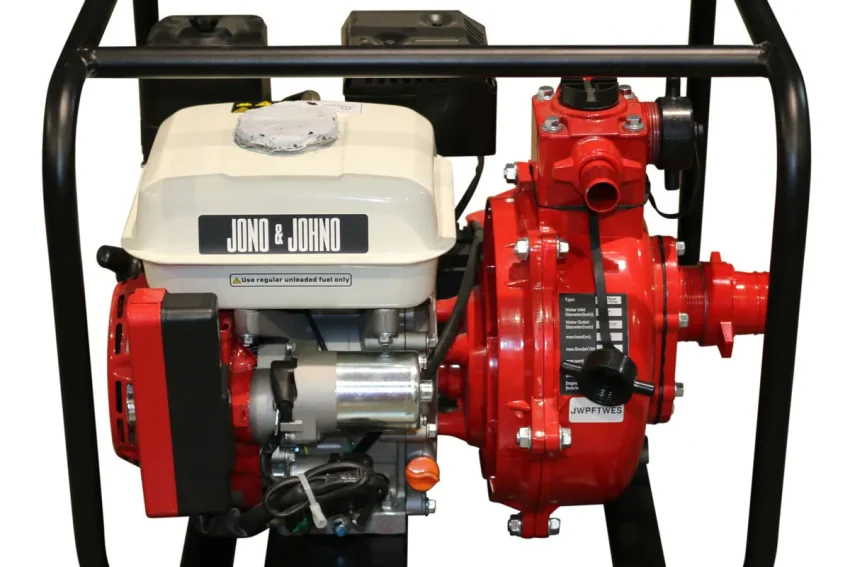

Selecting the Right Fire Pump

Choosing a fire pump starts with identifying the water supply and the desired pressure. Most residential fire pumps require a gasoline or diesel engine for dependable power. The pump should deliver enough flow, typically at least 100 gallons per minute, and maintain a pressure in the range of 60–120 psi for effective hose operation.

Matching the pump to the fire hose size is vital. Standard garden hoses are not suitable; a dedicated 1.5-inch fire hose is recommended for better flow and handling. Carefully reviewing options like portable and engine-driven models lets homeowners accommodate for terrain and distance from the water source.

Considerations for installation, such as using a solid, level base plate with shim adjustments, help prevent vibration and premature wear. Pumps should meet relevant standards, such as recommendations found in NFPA 20, which guides on fire fighting system installation and maintenance.

Water Sources and Storage Tanks

A reliable water source is essential for any fire fighting setup. Options include dedicated water storage tanks, swimming pools, ponds, or wells. Each source requires different fittings and suction arrangements to prevent air leaks and maximize pump efficiency. For areas without an ample year-round water supply, installing a storage tank with a capacity of at least 5,000–10,000 litres provides a buffer in emergencies. Tanks should be kept full and fitted with valves compatible with fire pumps and hoses.

Suction lines must be sturdy and kept as short as possible to maintain flow and pressure. If using a well, ensure the pump has enough power to draw water quickly. Filtration or screening at the intake prevents debris from damaging the pump or restricting flow.

Ensuring Safe and Reliable Operation

Safe and reliable home fire pump operation depends on a structured approach to inspections, planned maintenance, and careful equipment choices. Every component, from the pump to the fire hose, must be functioning properly and checked regularly to prevent failures when it matters most.

Inspection, Testing, and Routine Maintenance

Routine visual inspections help spot early signs of wear, leaks, or vibration issues in fire pump systems. Experts recommend that both diesel and electric fire pumps be inspected weekly, along with checks on the pump room for obstructions and hazards. Testing should involve running the pump under load and monitoring the performance.

During each inspection, the operator should check for fluid leaks, loose couplings, proper alignment, and the integrity of hoses. Pressure gauges and fuel or gas levels should be verified. Lubrication points and mechanical seals must be checked and serviced as needed.

Scheduled maintenance should include cleaning inlet screens, tightening connections, and testing the jockey pump if present. Consistent documentation of all inspections and service helps ensure the system will operate as expected under real conditions.

Pump Operation and Safety Checks

Starting and operating a fire fighting pump safely requires verifying power or fuel availability and confirming that system valves are fully open. Before engaging the pump, the operator should monitor the pressure gauge and listen for abnormal noises or signs of misalignment and vibration.

A brief test run monthly can help confirm all features activate correctly. It’s important to monitor for any pressure drops and verify automatic controls and alarms are functioning. The system’s jockey pump, if present, should also be tested to ensure it maintains line pressure when the main pump is idle.

Conclusion

Setting up a fire fighting pump at home requires careful selection of the right type of pump, proper installation, and regular maintenance. Homeowners should ensure the pump is installed in a well-ventilated area with reliable access and good lighting, as recommended by fire safety consultants. Weekly inspections and routine testing will keep the system ready for emergencies.

Clear planning, adherence to local fire codes, and consistent upkeep all contribute to a reliable home fire fighting setup.